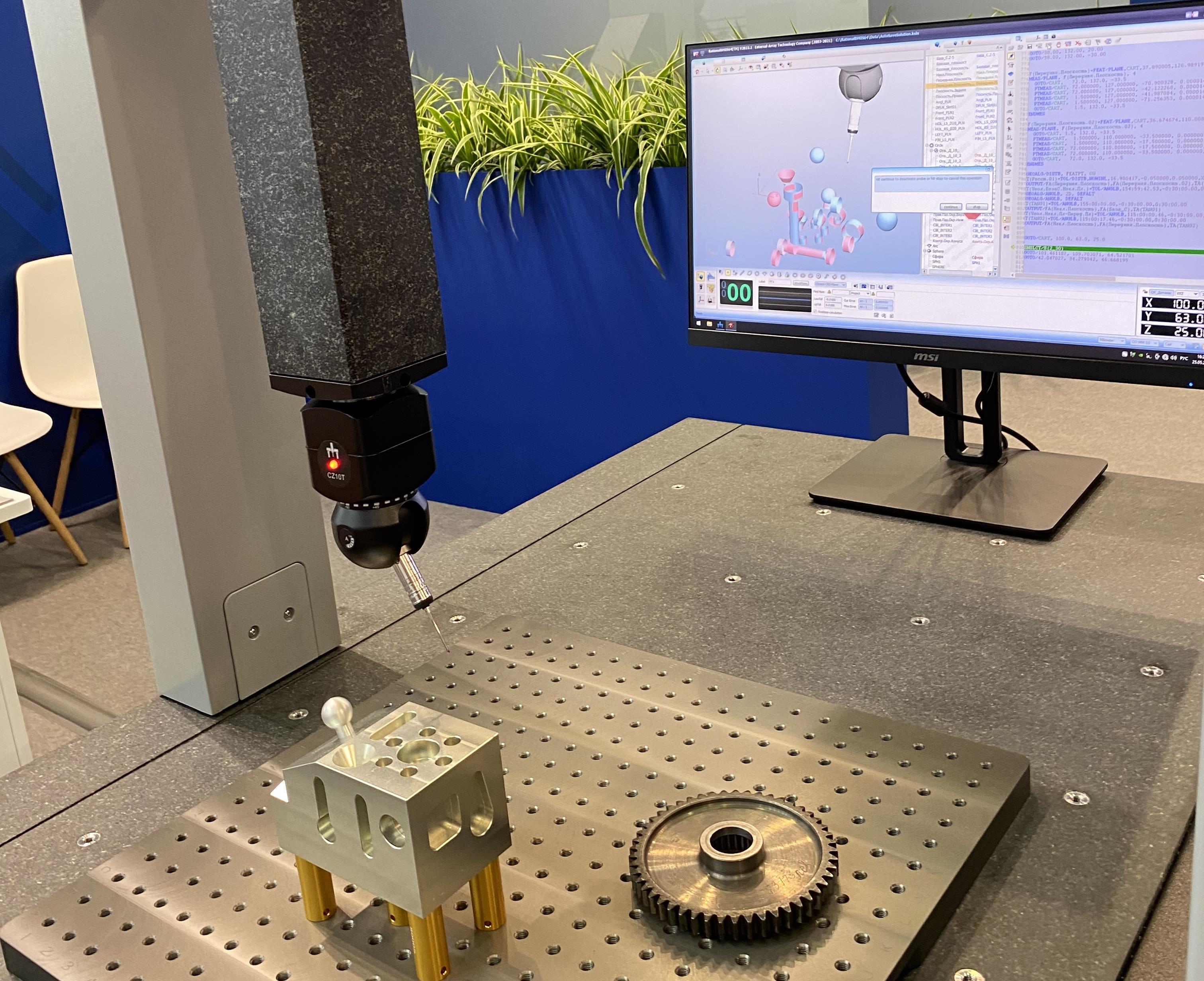

Computer aided quality

The CAQ module, which is connected to the software core, is developed on the basis of operating experience of automated digital measuring systems and tools in modern production and implements the following functionality:

- Downloading and editing the technological maps of measuring equipment in accordance with the change in the range of parts produced, drawings and quality policy.

- Timely calibration and control of the measurement error of the measuring equipment in use.

Using this module provides the following benefits:

- Minimization of the yield percentage of defective products

- Availability of quality data for the analysis of remote specialists

- Automatic change of work cycles and line changeover for new parts

- Monitoring of serviceability, calibration and calibration of the measuring equipment park